PRESENTATION 1.

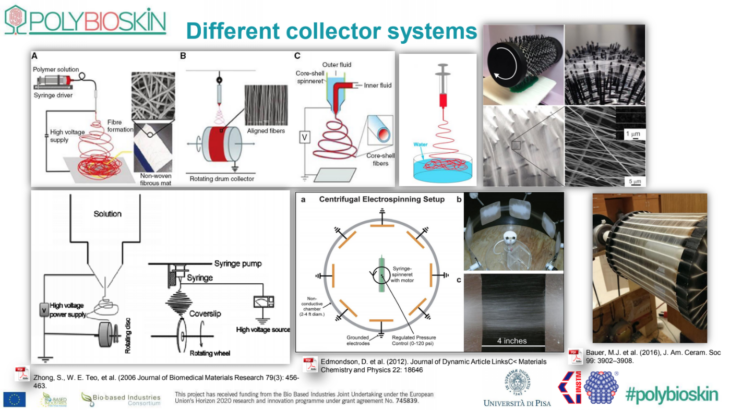

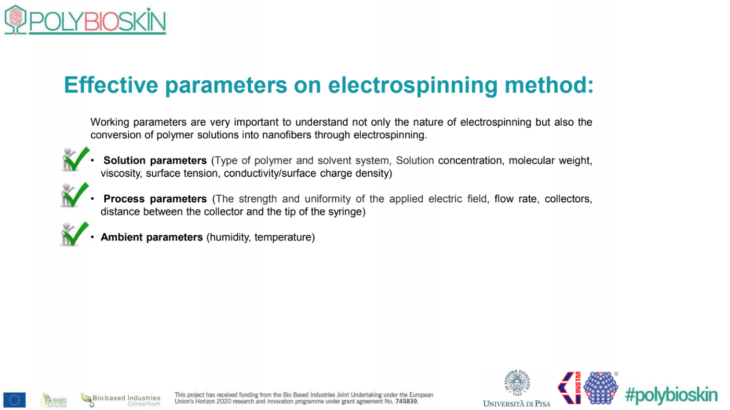

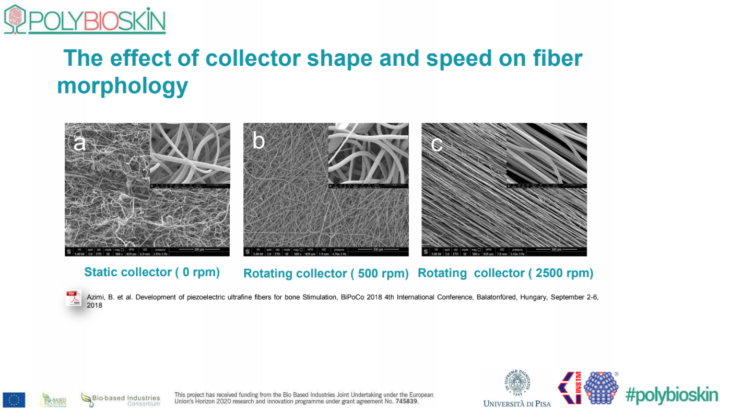

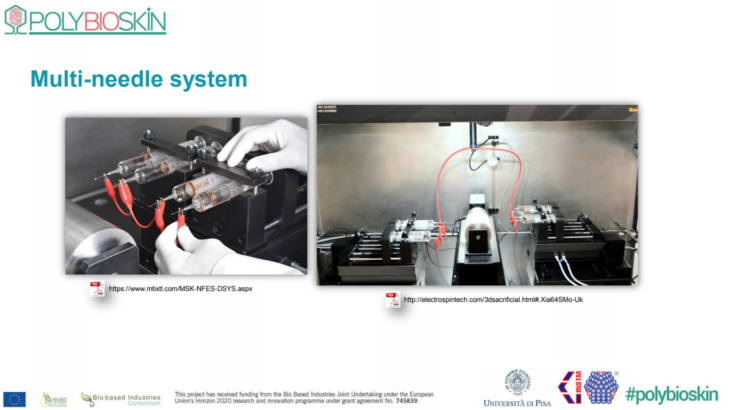

Electrospinning. Advantages & Applications

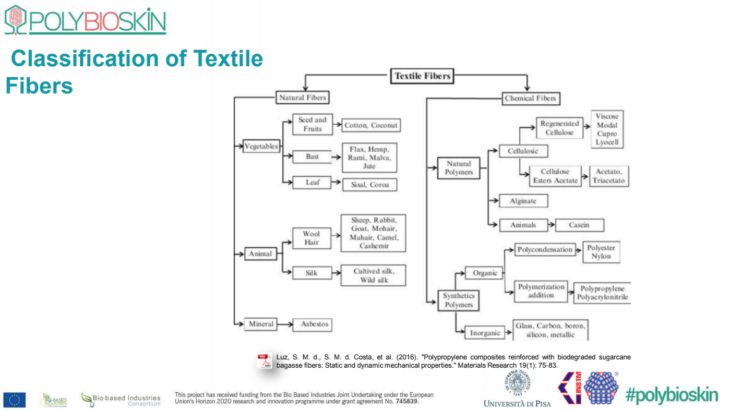

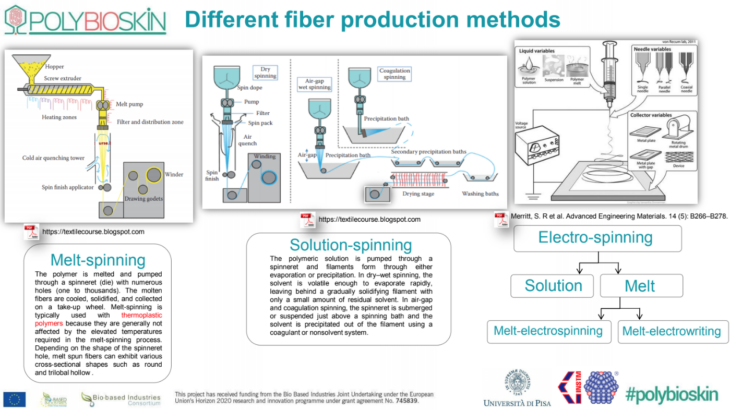

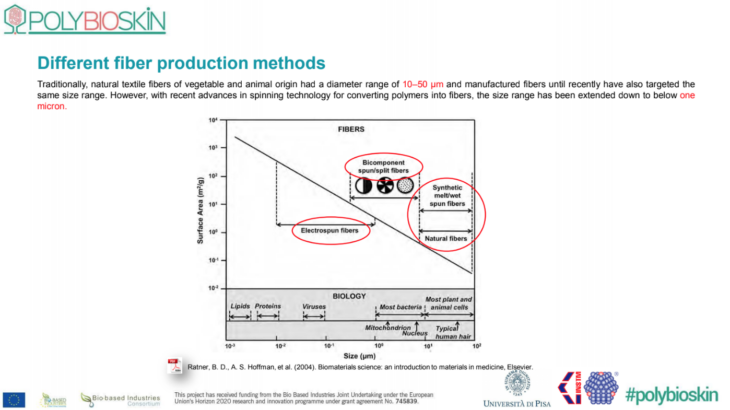

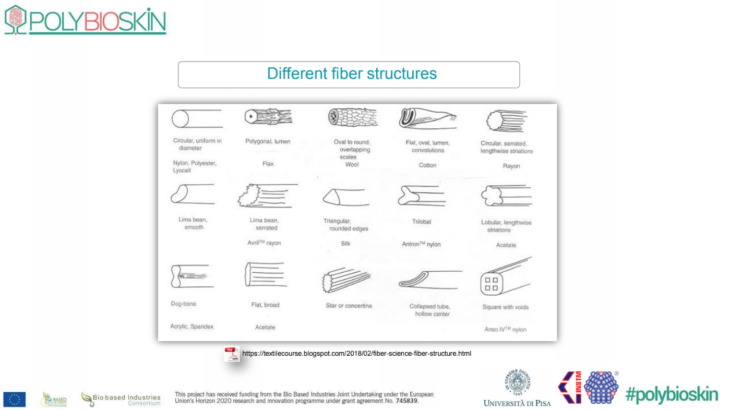

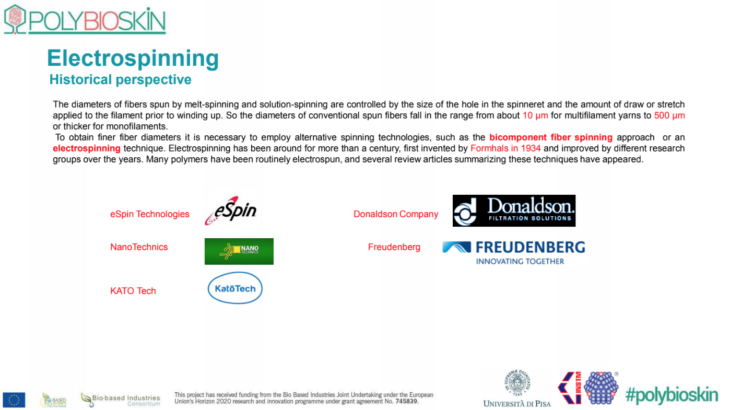

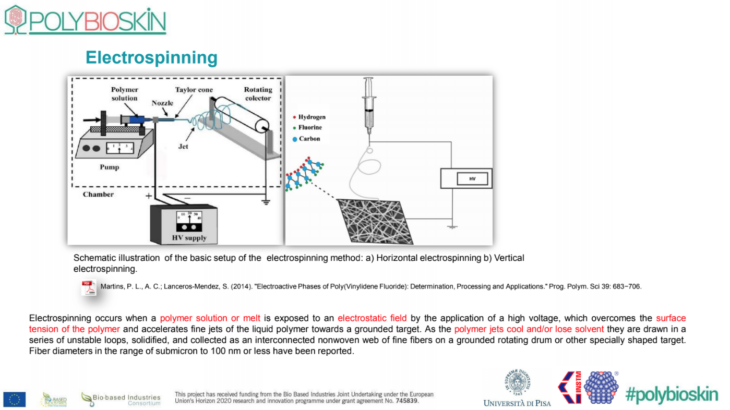

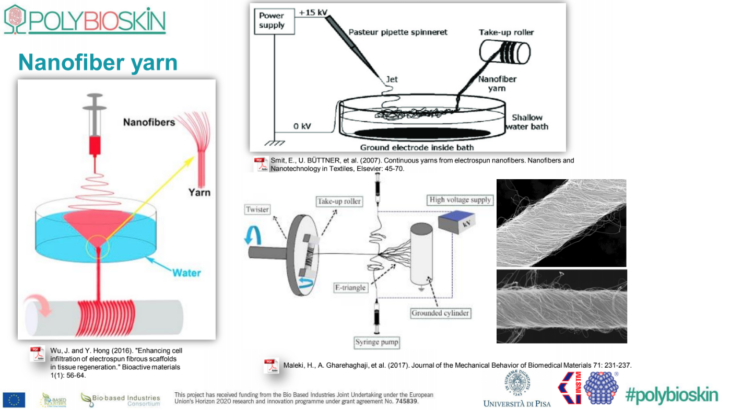

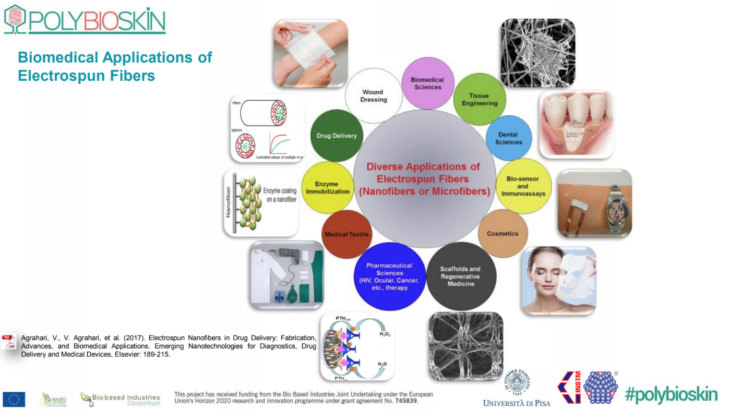

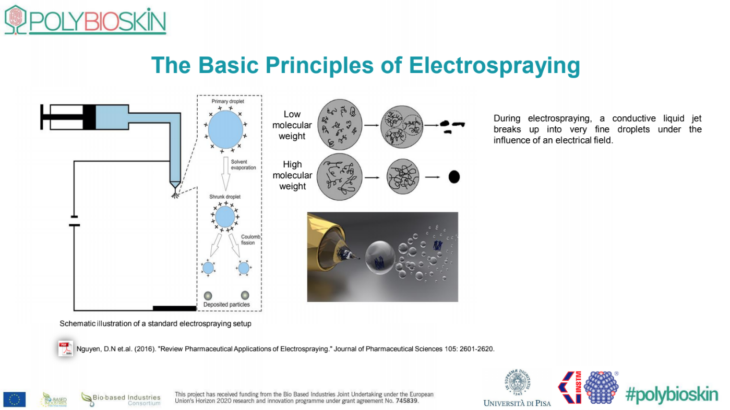

Textile fibers have been used throughout the history of mankind for different purposes. When at the beginning animal fibers and later on with on-going technology improvement also plant-based fibers (e.g. cotton, flax, hemp) and even mineral fibers (mineral wool) were used widely, with the rise of chemical industry, man-made fibers (made of natural or synthetic polymers) became more and more important. Electrospinning is one of many processes to produce fibers but is enabling POLYBIOSKIN’s bio-based nano-fiber production with advanced properties at a new level.

PRESENTATION 2.

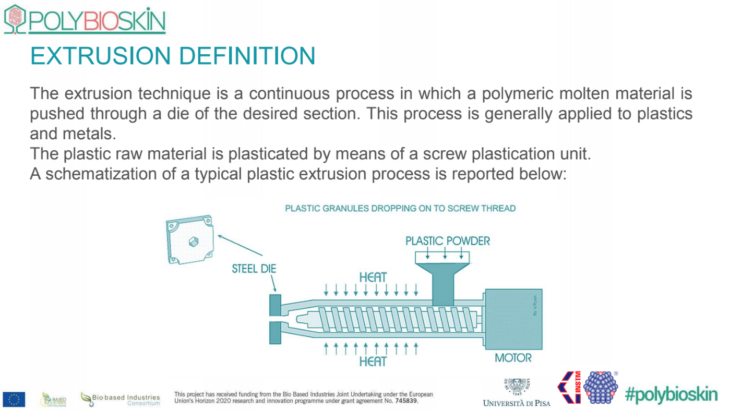

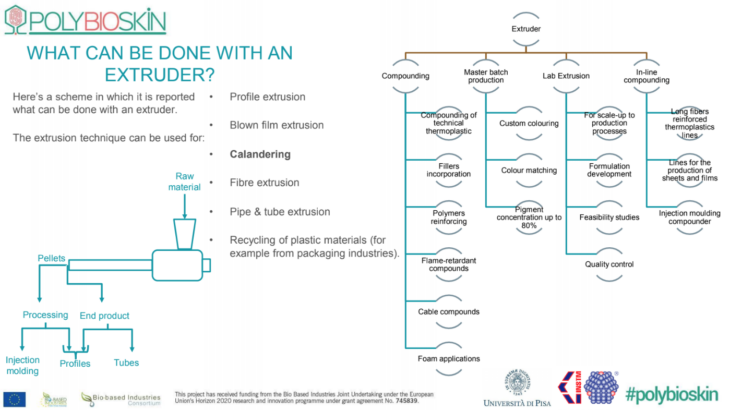

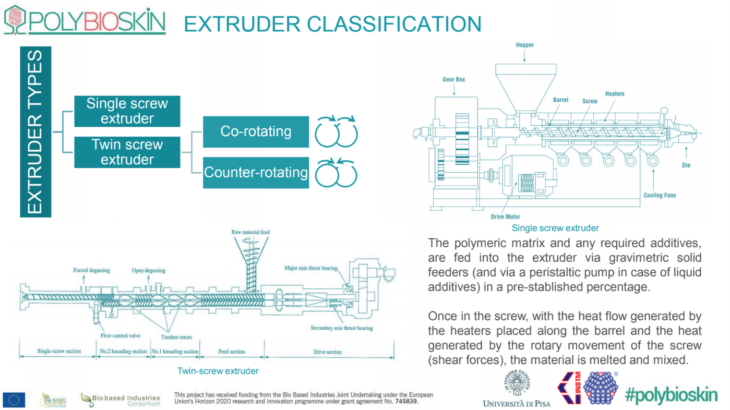

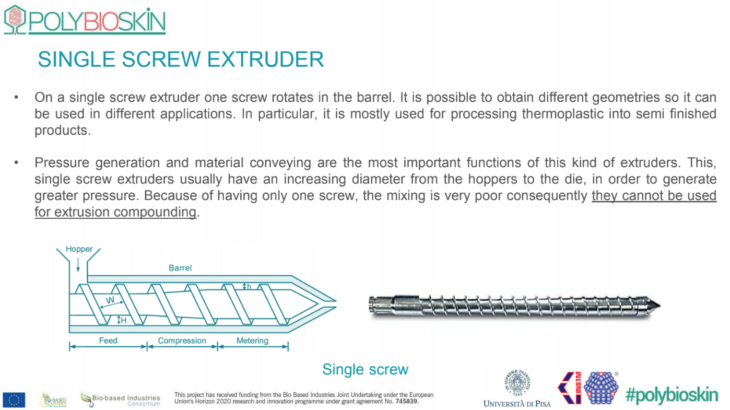

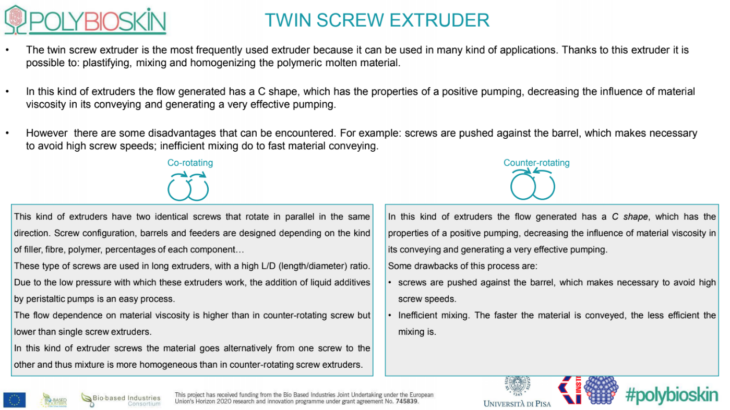

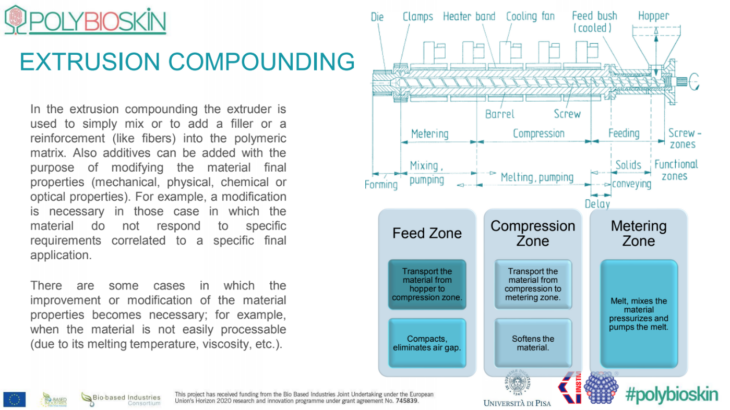

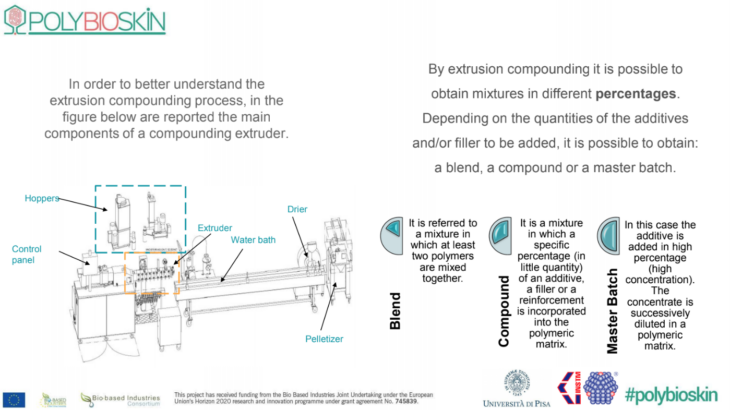

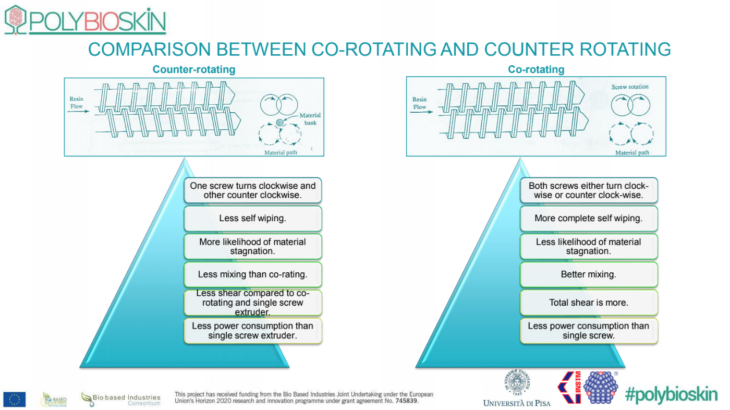

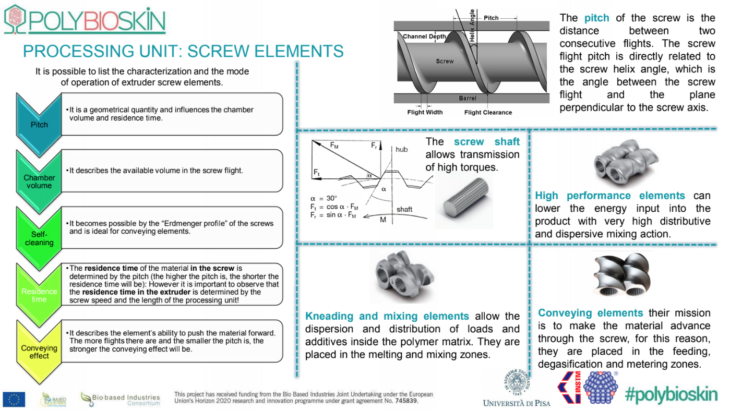

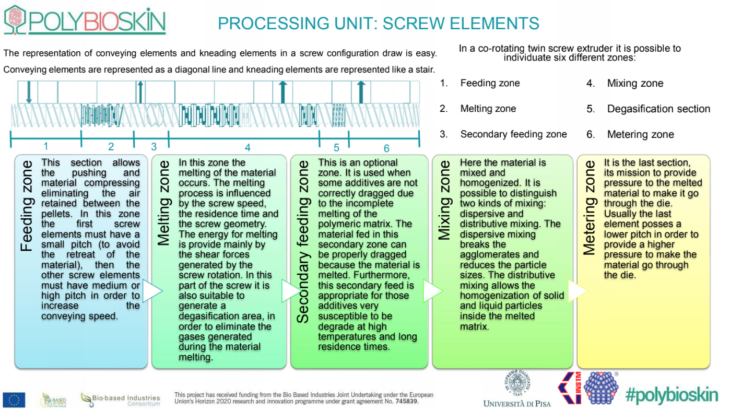

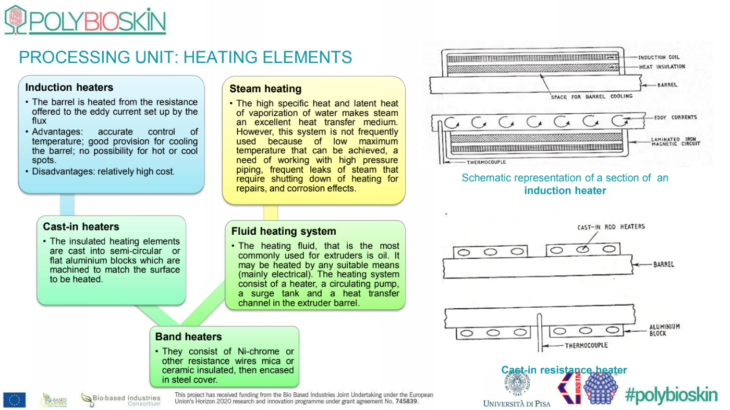

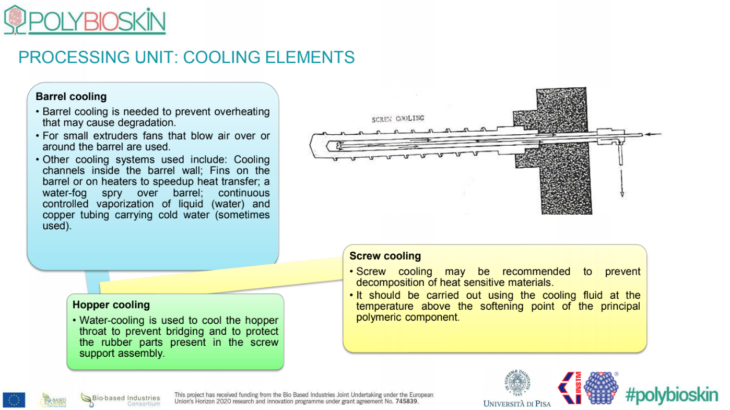

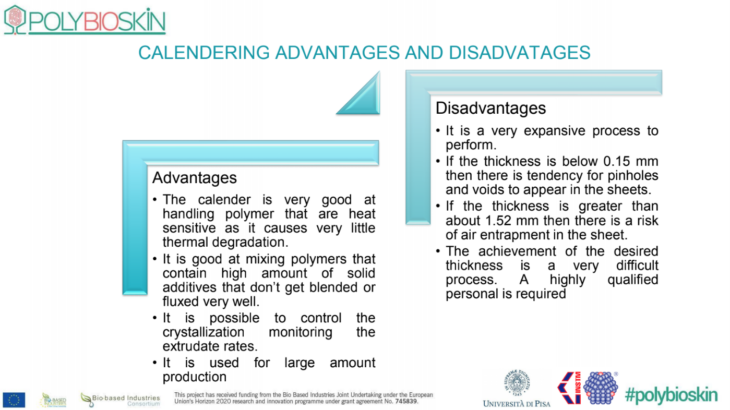

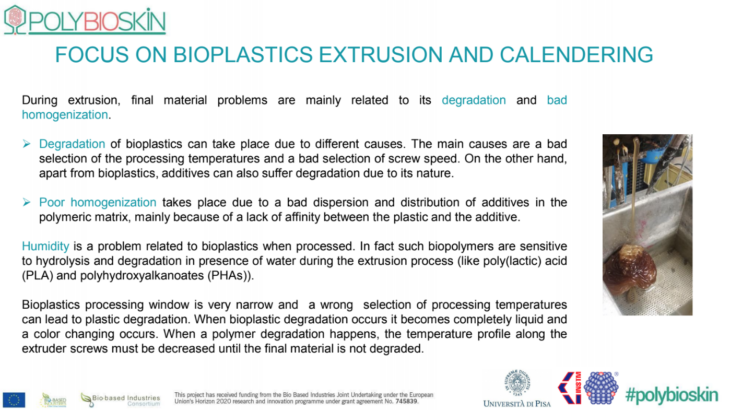

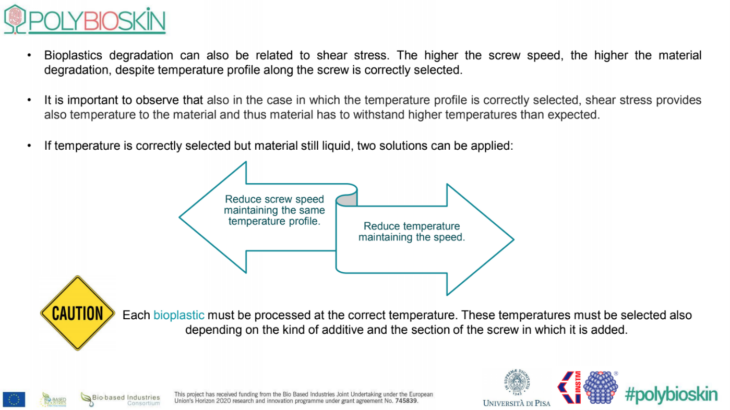

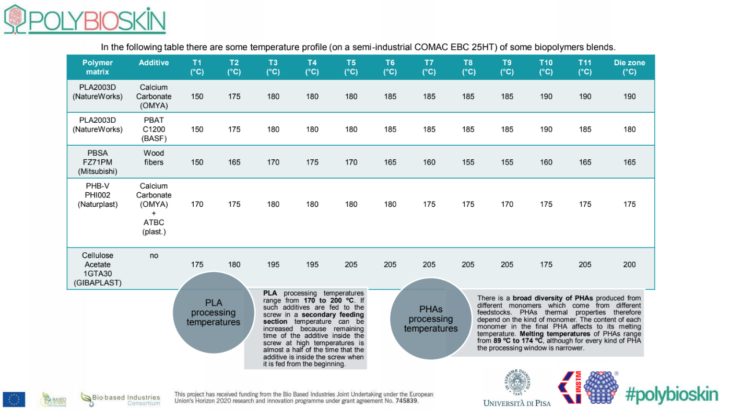

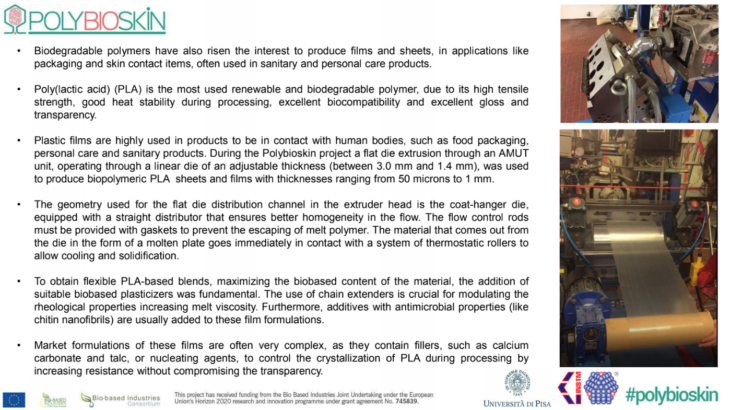

Extrusion Process and Calendering

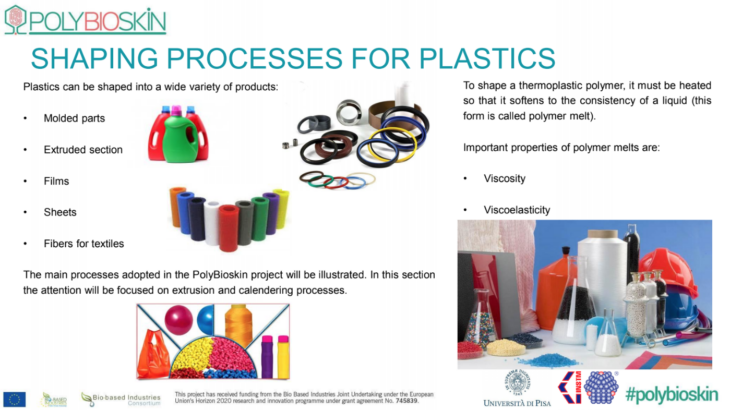

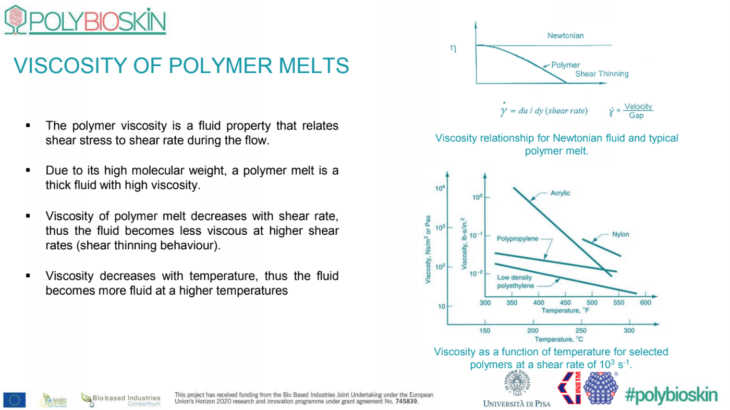

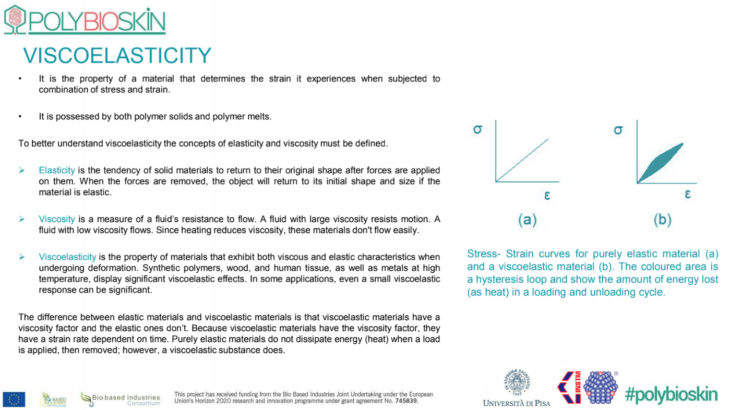

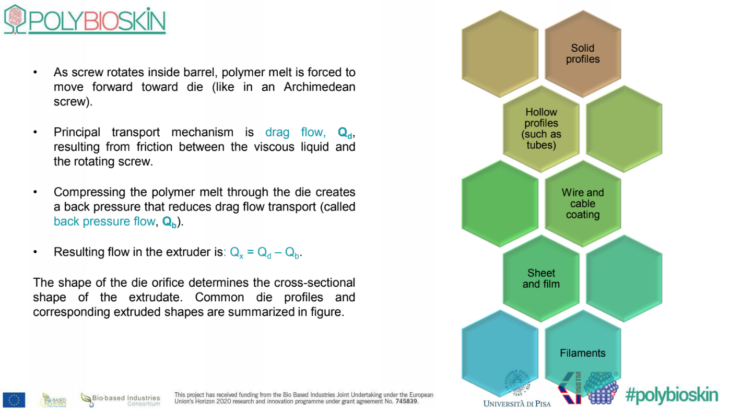

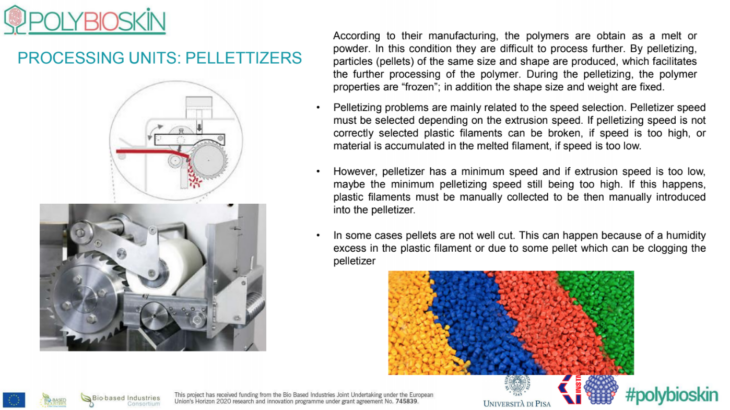

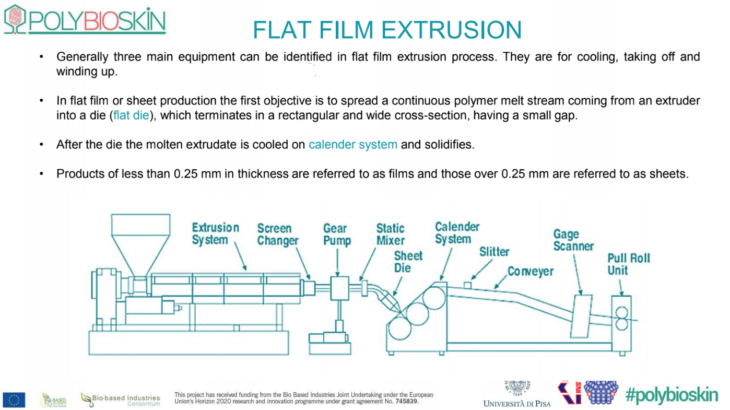

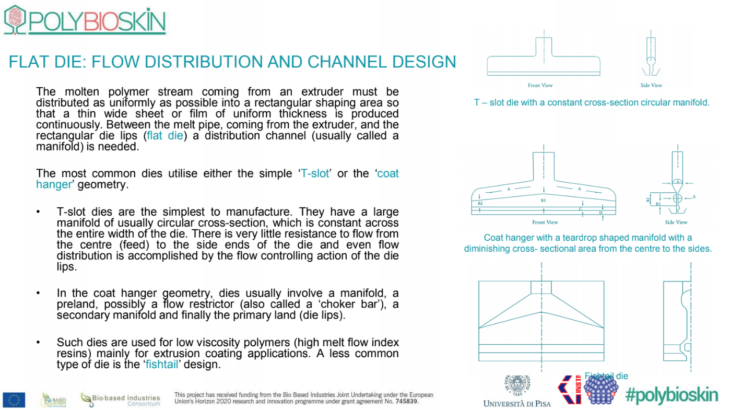

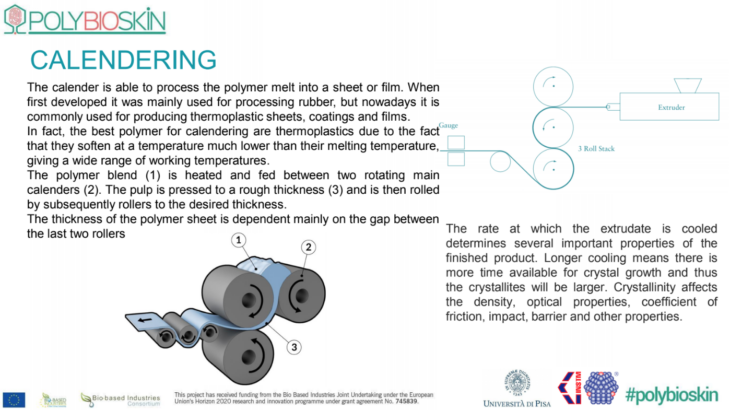

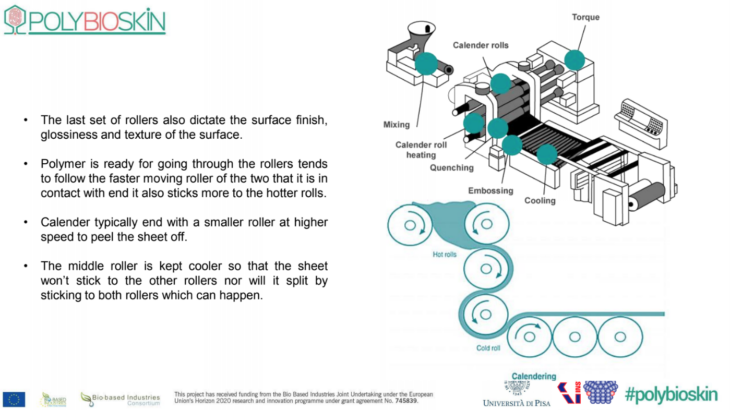

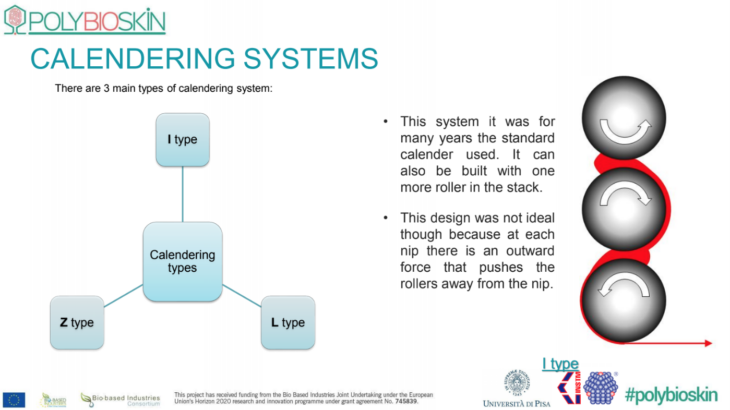

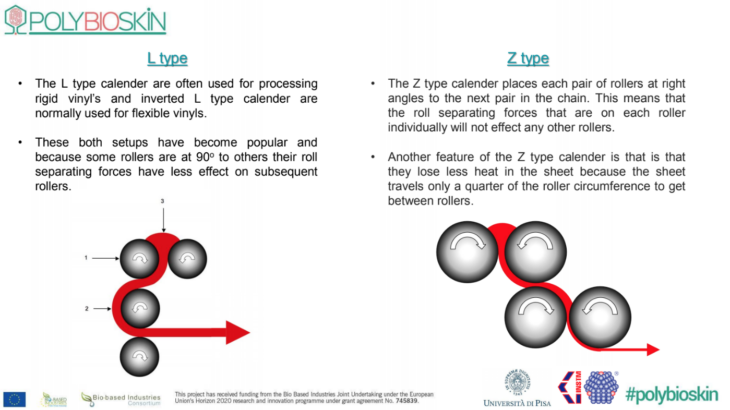

Most plastics, more precisely: Thermoplastic materials can be shaped into a wide variety of products, such as molded parts, extruded sections, films and sheets as well as fibers for textiles. To shape a thermoplastic polymer, it must be heated so that it softens to the consistency of a liquid (this form is called polymer melt).

The following presentation will give an overview on important industrial processes, needed for products made of plastics. This is the basis for all POLYBIOSKIN products.

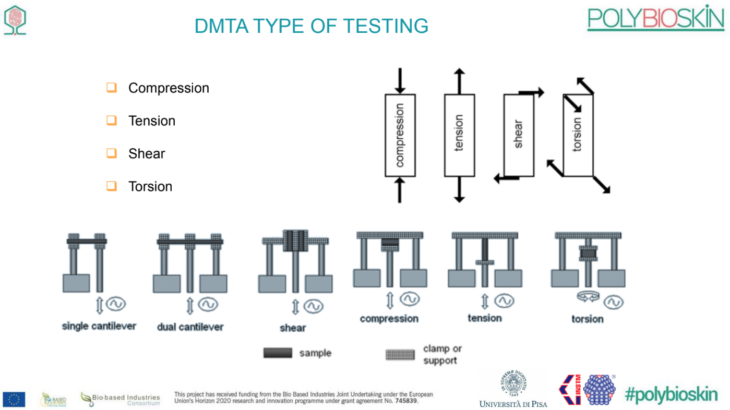

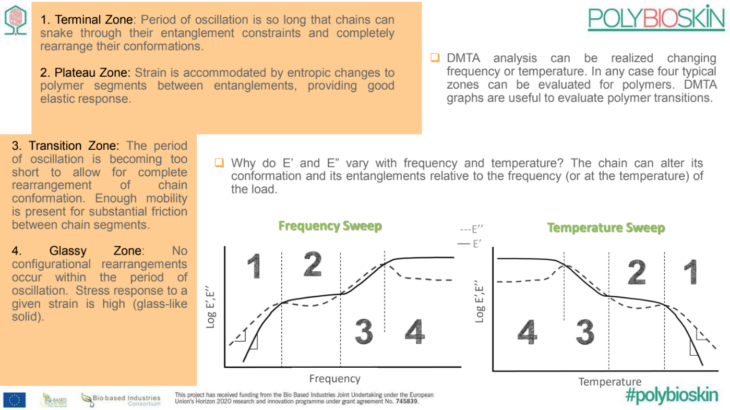

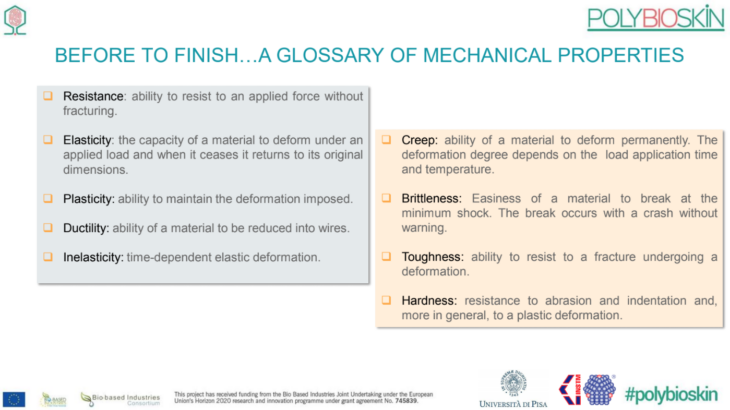

PRESENTATION 3.

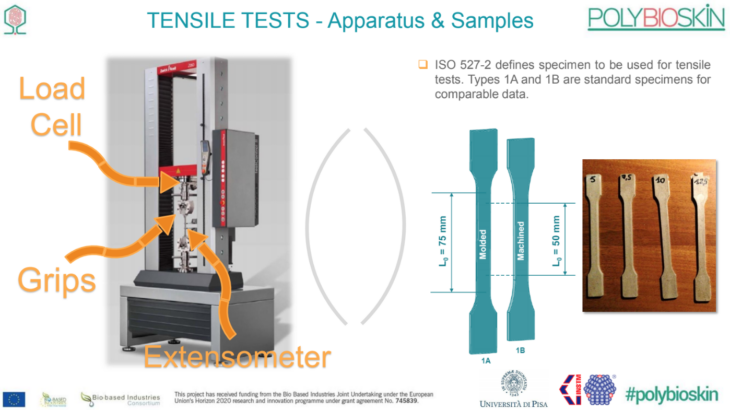

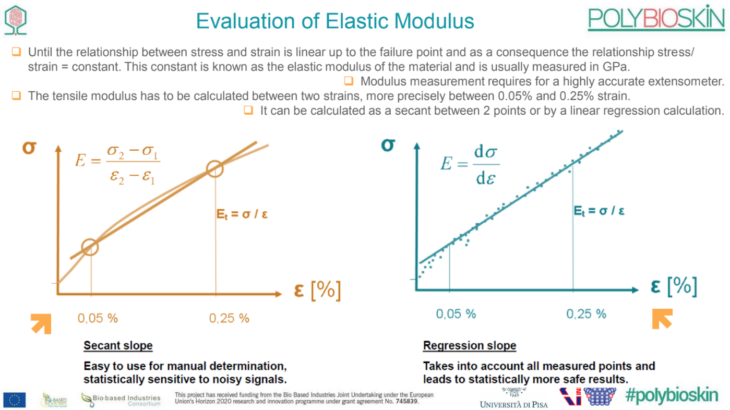

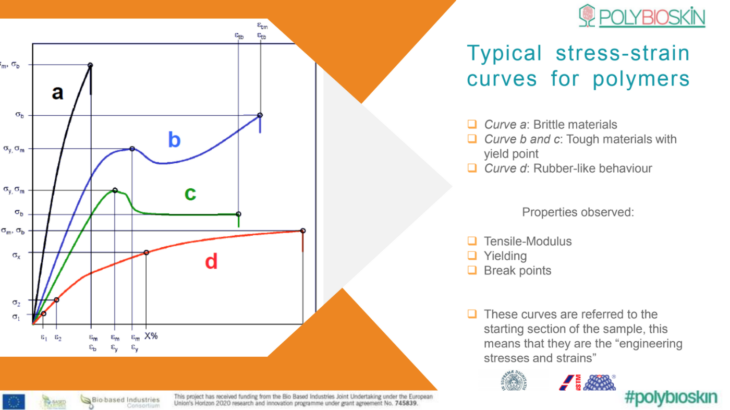

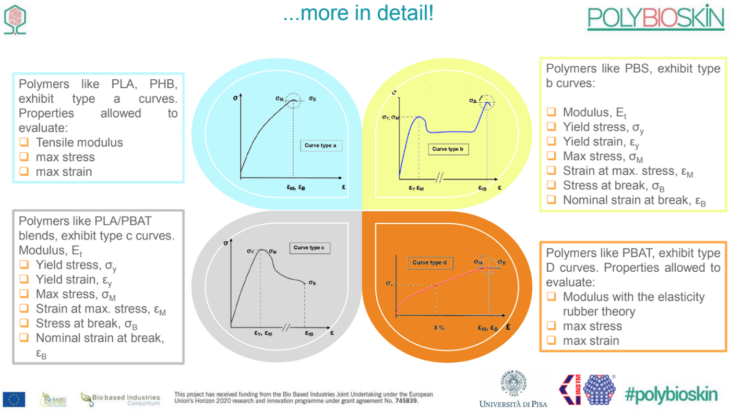

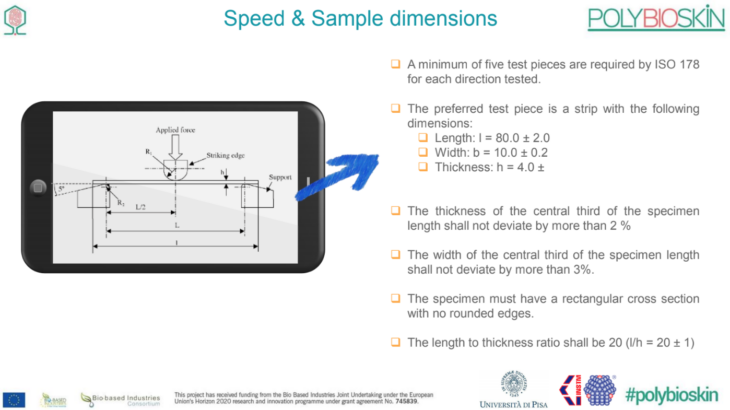

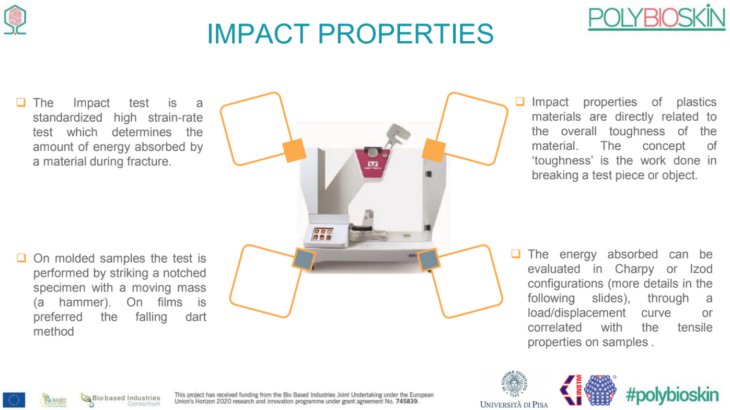

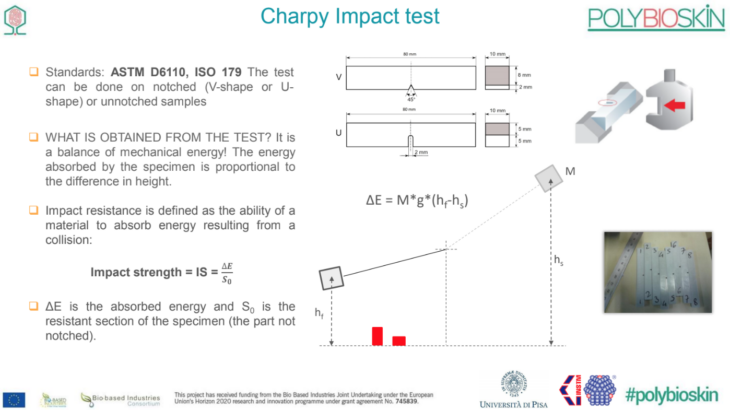

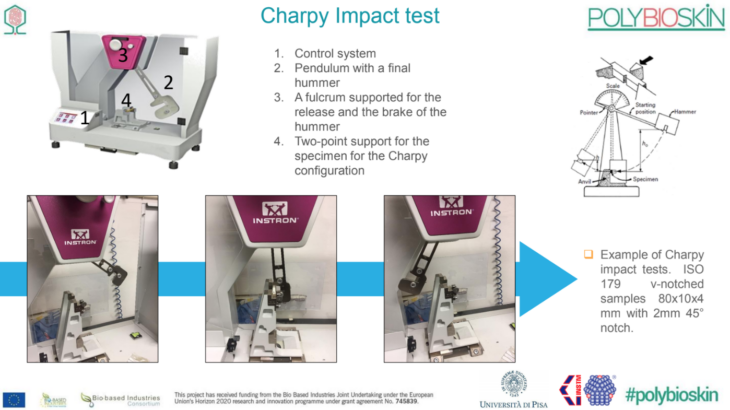

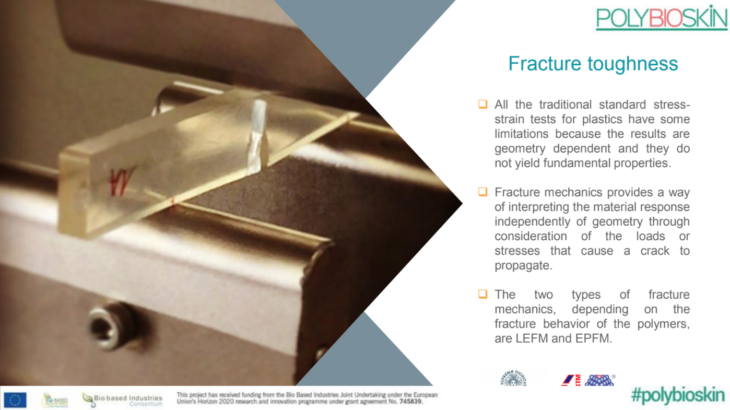

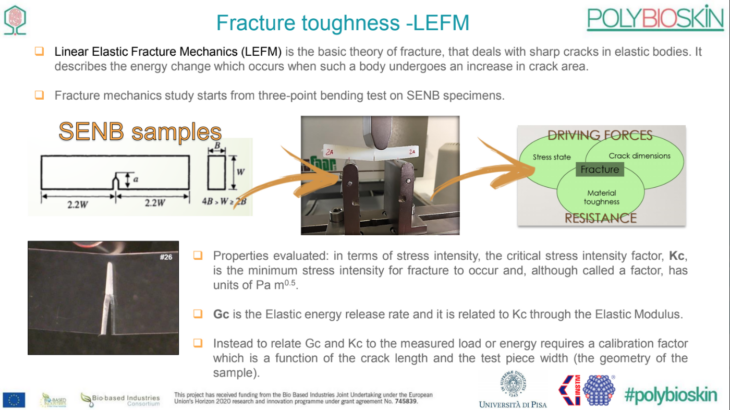

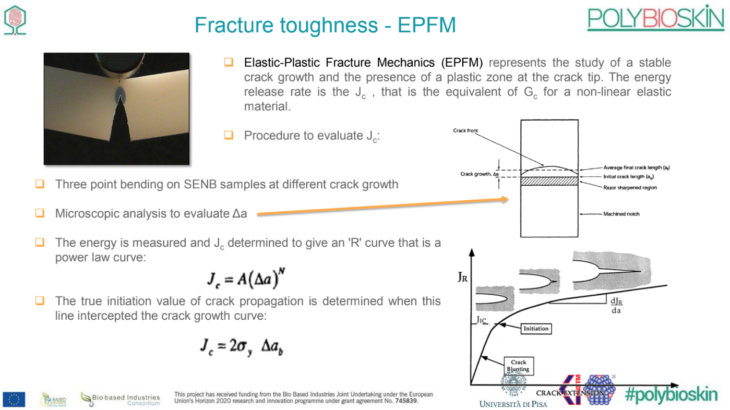

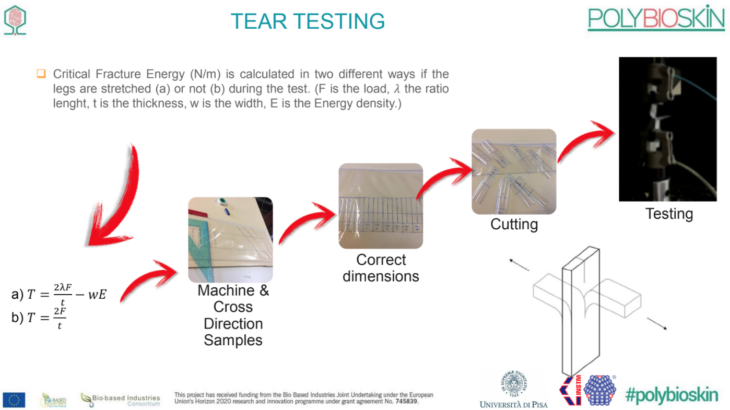

Mechanical Tests for Polymers

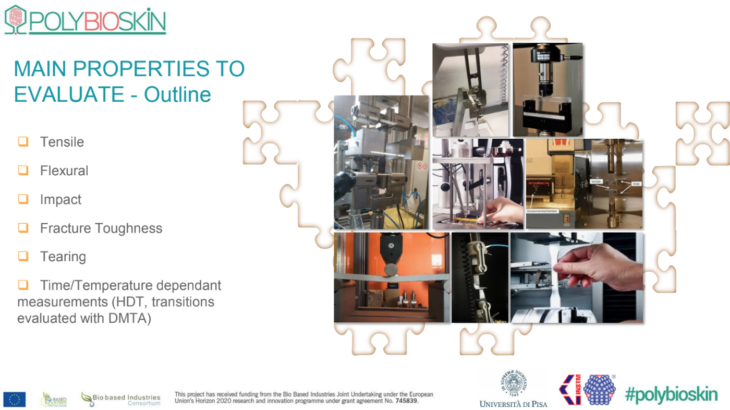

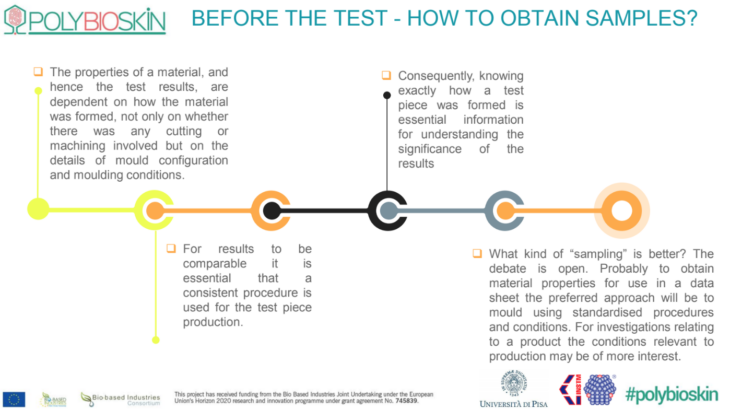

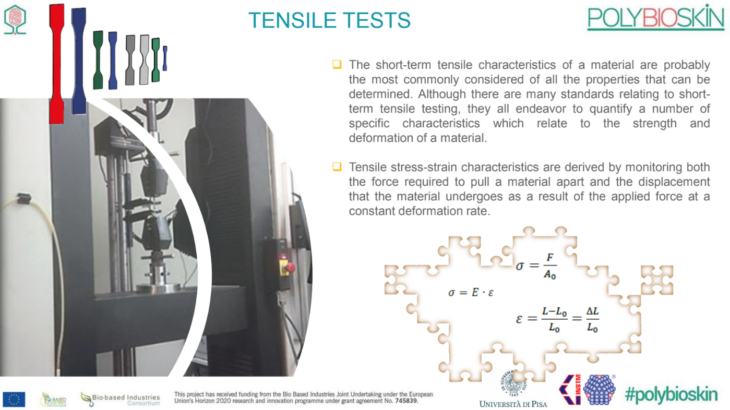

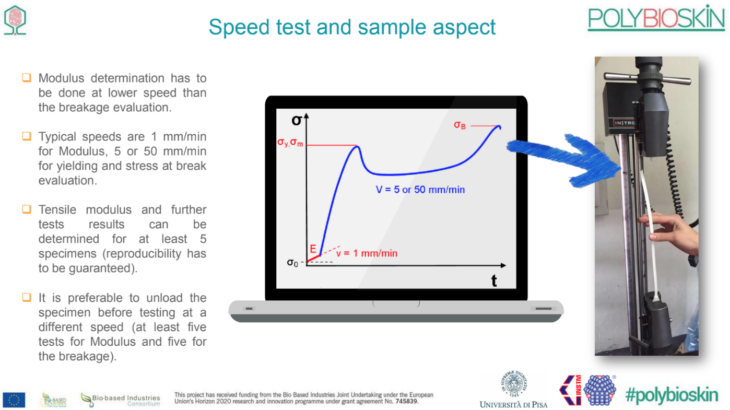

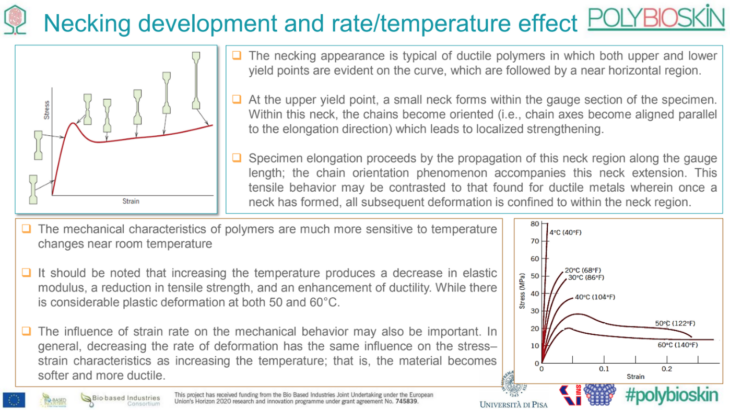

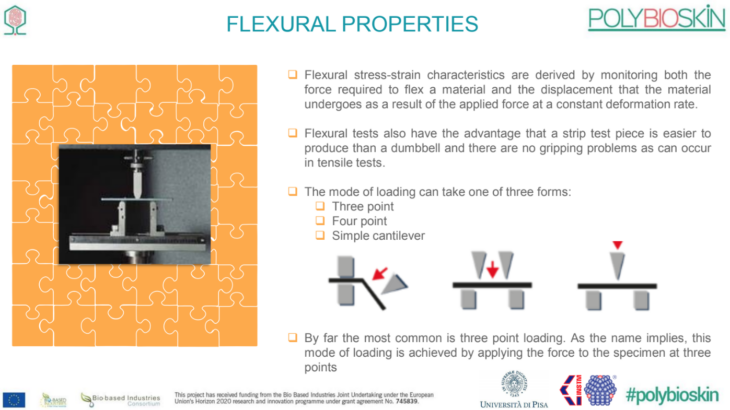

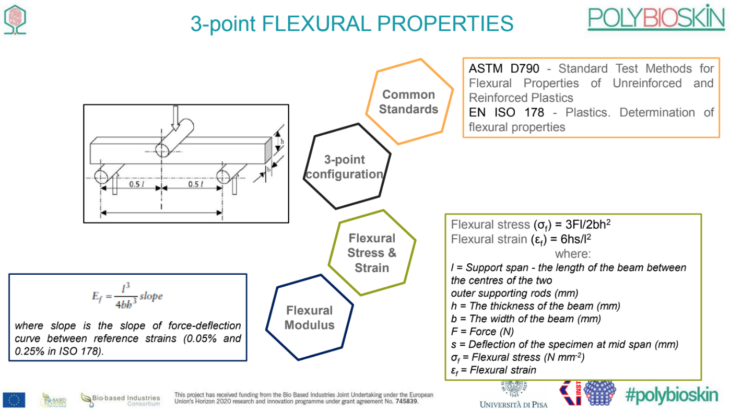

Mechanical properties express the ability of a material to resist actions caused by external forces tending to deform it.

Testing indicates qualitatively and quantitatively how the polymer will behave under certain real-life conditions.

Knowledge of the material properties is essential for several purposes, such as design, specification, quality control, failure analysis and for understanding the structure and behavior of new materials.

PRESENTATION 4.

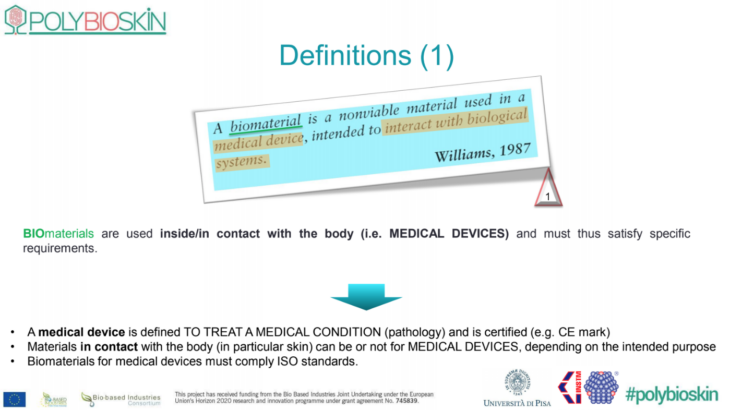

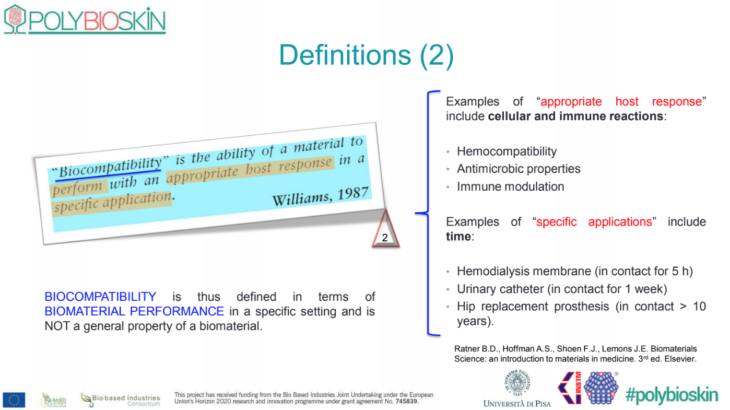

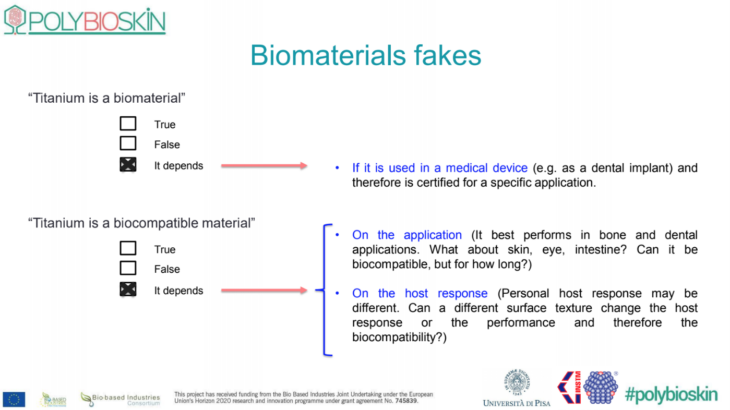

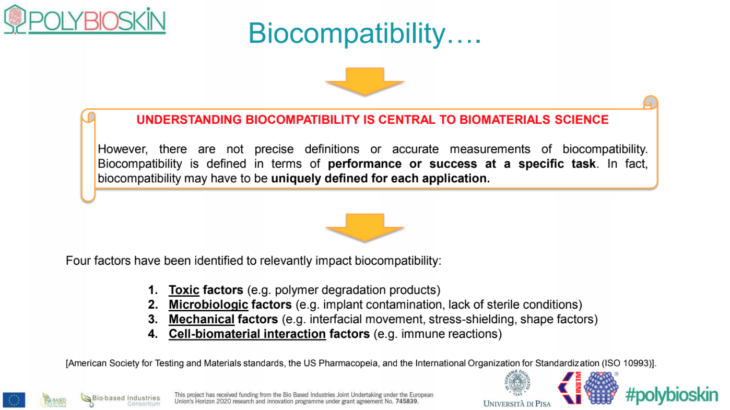

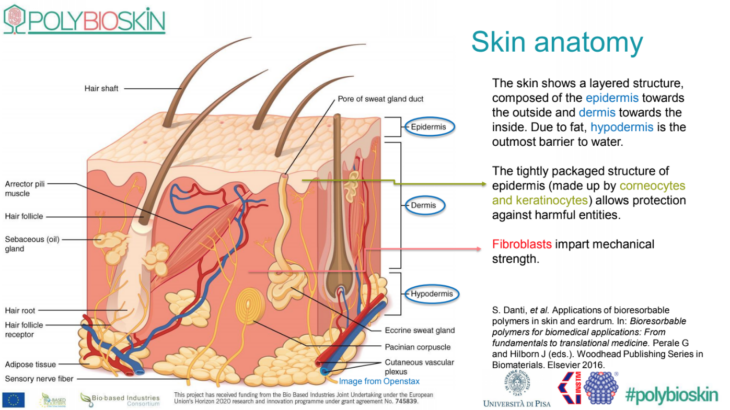

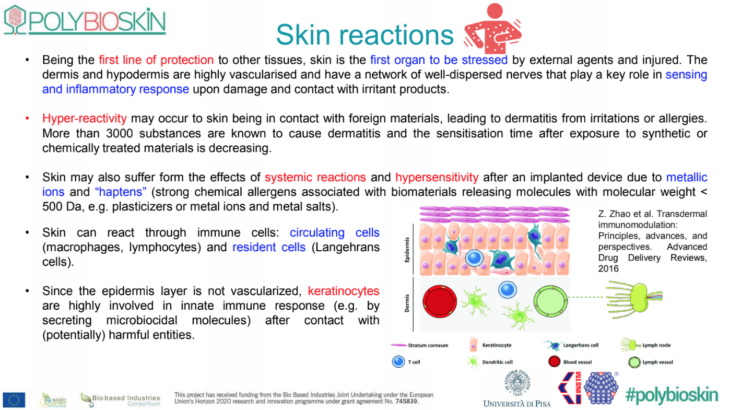

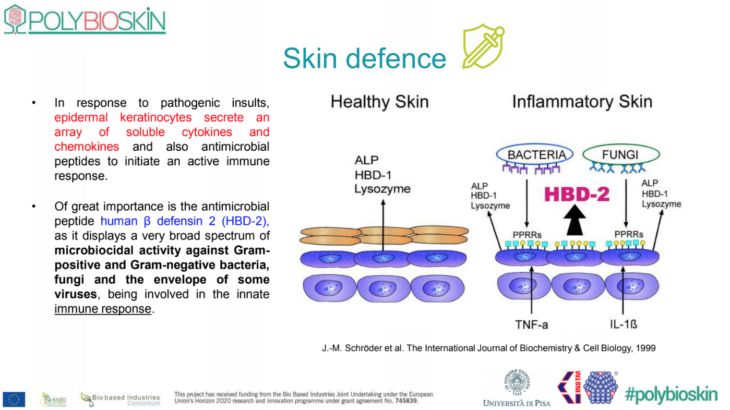

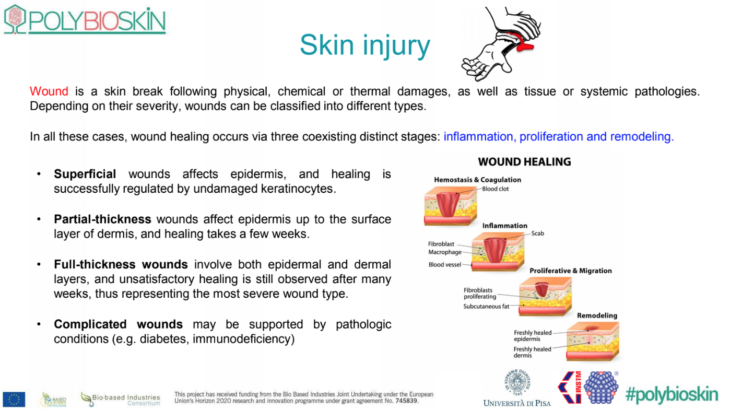

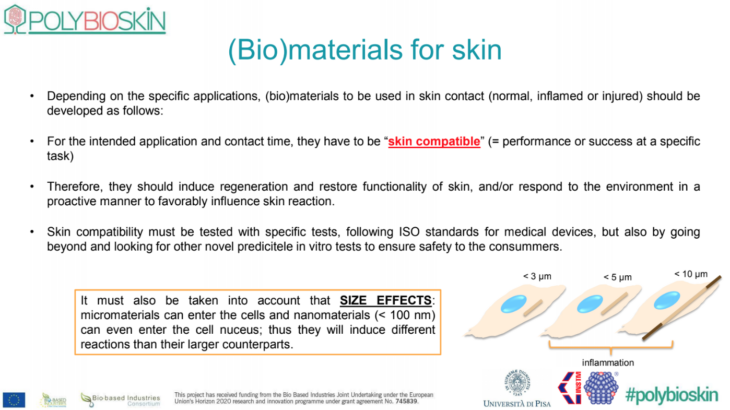

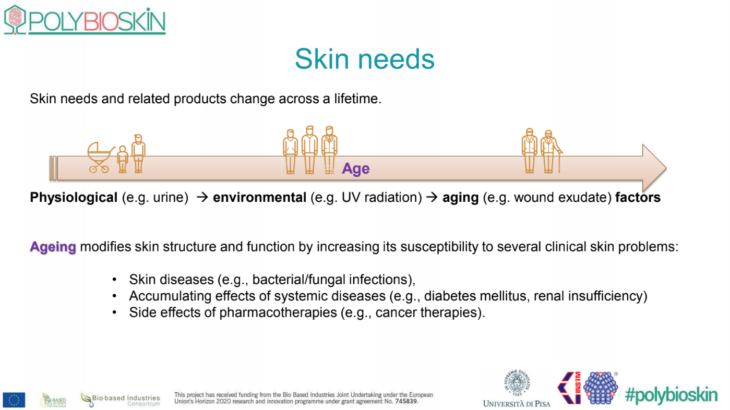

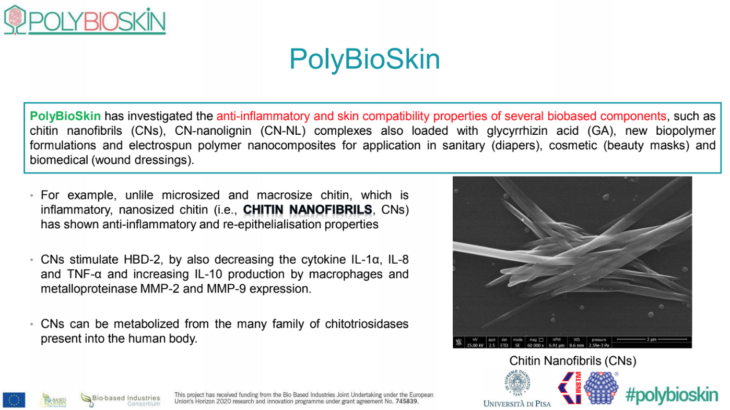

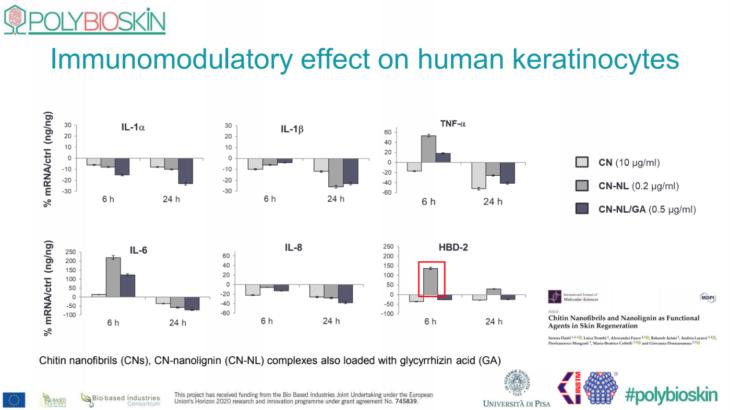

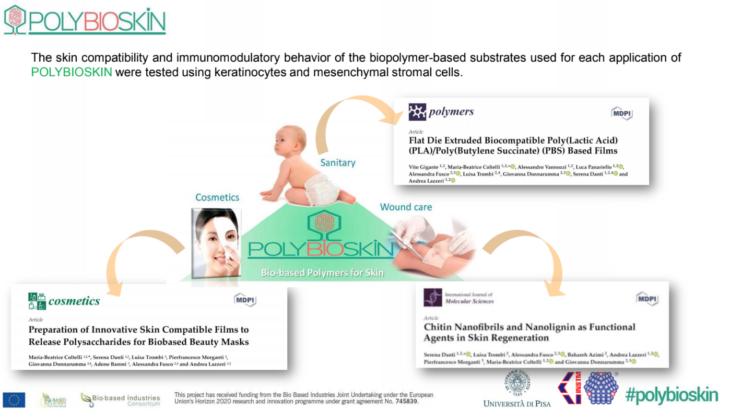

Skin Compatibility

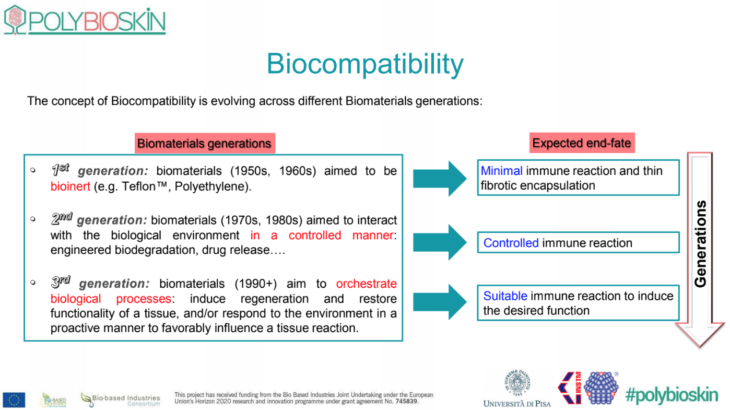

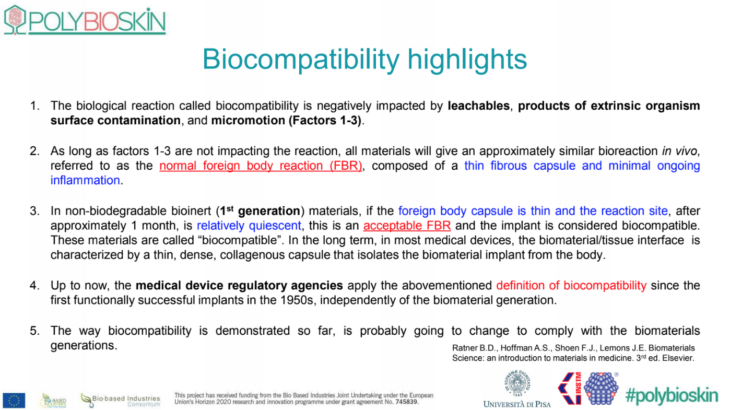

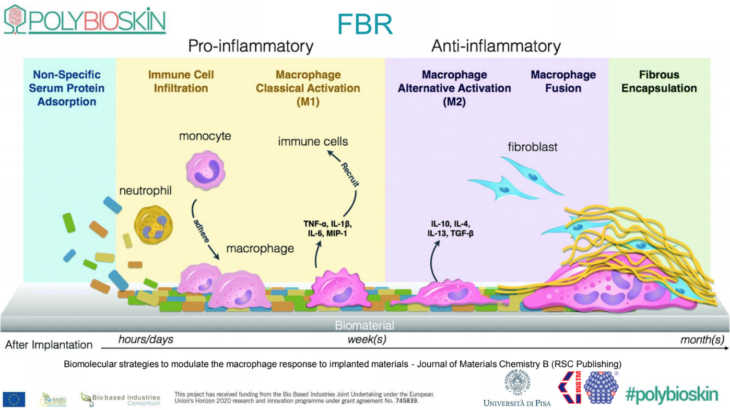

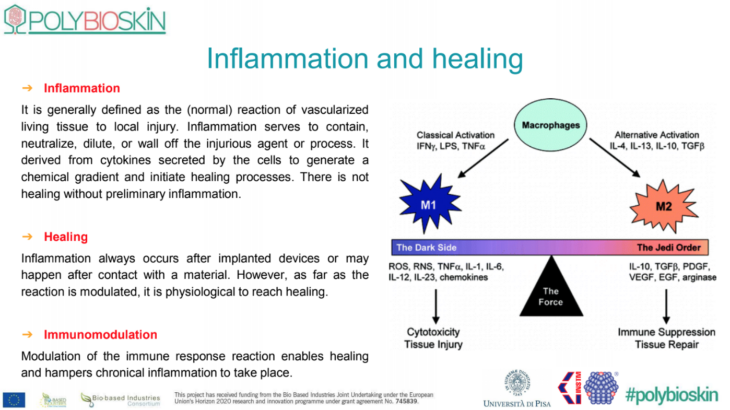

Skin compatibility means biocompatibility in general:

When using modified bio-based products, it is important to understand how the human skin works and how (bio)materials in skin care products can support it.

An overview on standards in skin product testing and first results describe how POLYBIOSKIN materials compete here.